Concrete Forming & Shoring

Request A Quote

Bold fields are required.

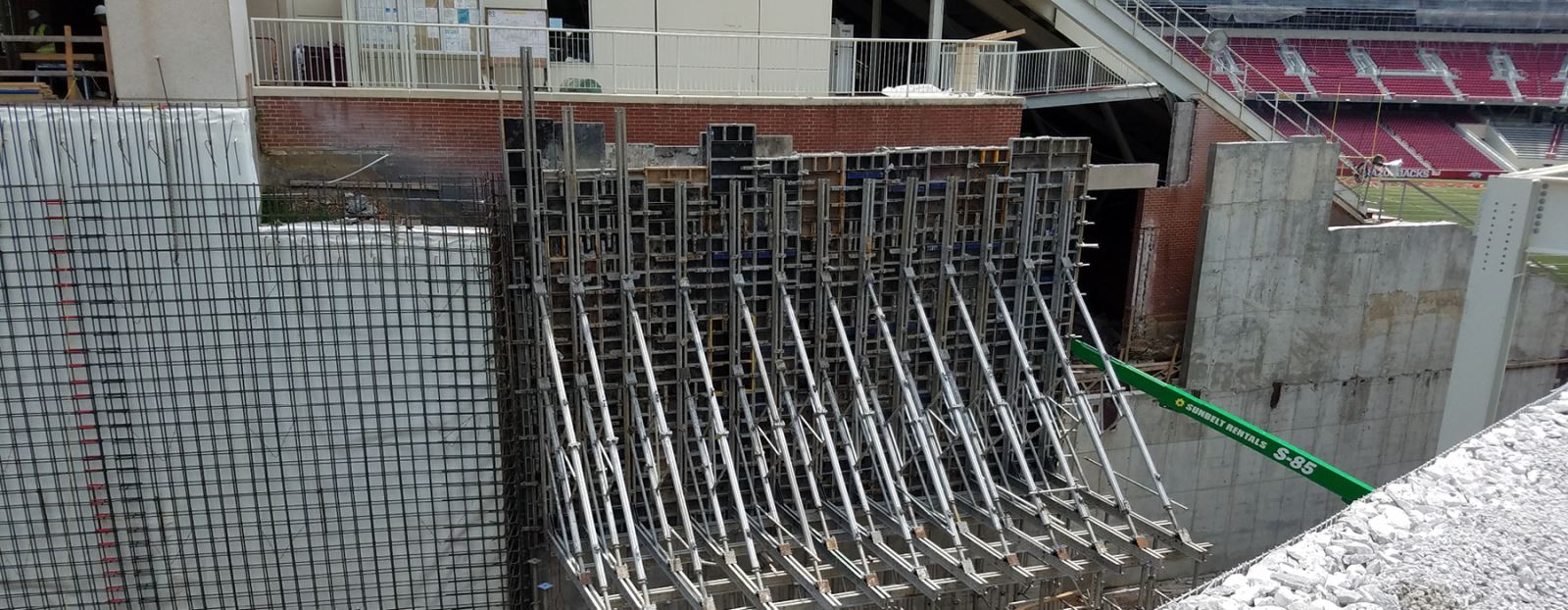

We help jobs take shape. With top-notch products, equipment rental, and solutions using gang and handset forming systems from leading manufacturers, such as SureBuilt, Gates, and Doka.

We are proud to have provided forming for Baptist Health, University of Arkansas, ARDOT, and other large-scale construction projects.

We rent, sell, and deliver concrete forming and shoring products. Our services include pre-budget and design estimates, full job quotes, engineering services, as well as on-site training. Working with the industry's top manufacturers we supply a variety of systems including Modular Handsets, Frami, Shoring, Aluminum Beam Gang, 10K shoring, and various plywood systems.

Concrete Forming Systems

Doka Framed Formwork Frami Xlife

Frami Xlife is a complete system, which also comprises high-performance safety and workplace accessories. The Frami Xlife panels are lightweight and easy to handle, so they can be erected very quickly by hand, without the use of a crane. On sites with a crane, it is also possible to lift several panels at a time, in a gang-form. The ingenious modular design makes for optimum adaptability to all job site conditions.

Click the buttons above to learn more.

Safety First

- The Frami safety tie off handle meets OSHA requirements

- Three safety handles per 9ft. panel

Switch to Gang Forming at Any Time

- No additional hardware is needed to switch from hand setting to gang forming.

- Lifting core units with one crane pick

- Cover 100% of the jobsite with one system

- Hinged and adjustable pilaster forms make pilasters a snap

- The Framax Stripping corner attaches and allows the fastest strip possible for cores

- Fillers are available in 6" increments plus 2", 1 ½" and 1" steel fillers

- Columns are formed with universal panels up to 36" - only one panel size for the whole job

- Eliminates various required filler sizes and saves time and labor in storing, sorting and finding specific width panels

Slashes Handset Labor Costs

- 80% fewer connections with only 3 clamps per 9ft. panel

- 75% fewer ties with only two ties for a 9ft. high pour, up to 13.5sq.ft. per tie

- Uses the lightest fastest clamp - only 2.6 lbs. and it goes on with one hand

- No wood walers are required

- Form columns faster. Universal panels form up to 36” square columns.

- Reduces your maintenance costs. No rust with a hot dipped galvanized frame. Longer plywood lifespan with all birch plywood that is protected by the frame and edges sealed with hot caulking.

Shoring

The framed formwork system that uses only a very few different panel formats to achieve a consistent 15 cm increment-grid, no matter whether the panels are stood upright or on their sides. All the connectors and accessories fit seamlessly into this grid – making for fast forming-times and high efficiency.

Cost-Effective Rapid Working Easy Handling & Planning Superlative Concrete Results Comprehensive Workplace Safety

Click the buttons above to learn more.

Comprehensive Workplace Safety

- Safe vertical access with the Ladder system XS

- Workplace safety on all sides with the Platform system Xsafe plus

- Practical accessories – such as panel struts, lifting/repositioning devices, 3-in-1 pole tool etc. – make for safe, easy handling of the formwork

Superlative Concrete Results

- Clean concrete finish from the high-grade Xlife sheet with its plastic-enhanced surface

- The ingeniously co-ordinated panel size-grid permits a neat joint pattern even when combining upright and horizontal panels

- No screw imprints in the concrete, as the formwork sheet is screwed on from the rear

- The neat negative frame-imprints in the concrete minimise any finishing-work

Easy Handling & Planning

- The ingeniously co-ordinated panel formats, with their logical size-grid, help you make optimum use of formwork commissioning quantities

- Having only five panel widths makes for easy planning and forming, and efficient logistics

Rapid Working

- Forming-times are kept short by the widely spaced form-ties (up to 1.35 m apart)

- Rapid forming possible thanks to large-area gangs or extra-large panels

- With a high-pressure washer, final and intermediate cleaning is easy, thanks to the panels' powder-coated frames and sturdy timber-plastic composite sheets

Cost-Effective

Slash handset labor costs with lightning-fast assembly:

- High numbers of repeat uses made possible by its excellent manufacturing quality and extra-durable Xlife-sheet

- Smaller number of (expensive) closure zones, due to the consistent 15 cm increment grid.

- The widely spaced form-ties (1.35 m apart) save up to twelve percent of the costs for ties and finishing-work on tie-holes.

- Galvanised, powder-coated steel frame, for long lifespan.

- Compact gang-forms mean less crane time is required.

- Using the single-side-operable tying system Monotec optimises workflows in confined spaces as well.

- The ingeniously coordinated panel formats, with their logical size grid, help make optimum use of formwork commissioning quantities.

- Having only five-panel widths makes for easy planning and forming, and efficient logistics.

- Reduce your maintenance costs. No rust with a hot-dipped galvanized frame. Longer plywood lifespan with all-birch plywood that is protected by the frame and edges sealed with hot caulking.

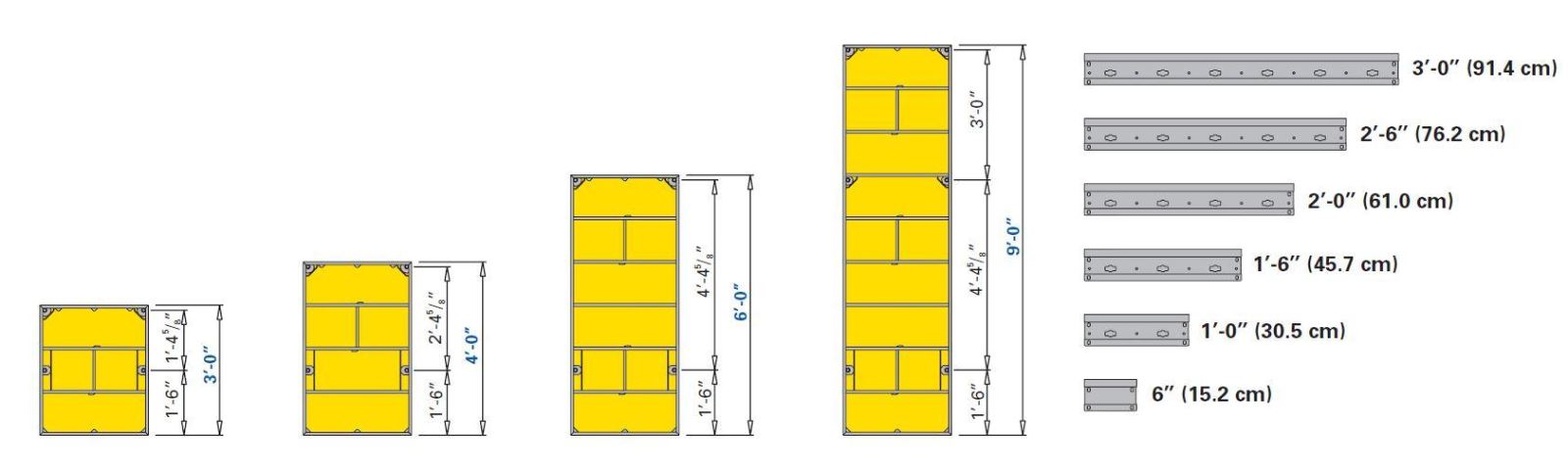

Modular Handset

The most productive, pre-engineered, reusable, factory-built concrete forming system in use today. It is designed for maximum versatility and can be used to form virtually any concrete structure.

Save Time Save Materials Efficient for Curved Walls Work Safely

Click the buttons above to learn more.

Work Safe with the Quick Hook Handle

Its exclusive design meets the Occupational Safety and Health Administration (OSHA) requirement for fall protection (Subpart M).

- The Quick Hook Handle is integral to the panel design with staggered locations between the cross members. This provides convenient climbing and attachment points for personal safety equipment. This design improves worker safety without any reduction in productivity.

- The same Quick Hook Handle is used to carry the panel. The design provides enough clearance for hands, but does not interfere with panel stacking for storage.

Efficient for Curved Walls

Two-foot-wide panels readily form curved walls down to a 15' inside radius (30' diameter). Standard fillers can be used to form smaller radius walls, for example 8" fillers are used to form a 5' radius. One inch, 1½" and 2" fillers adapt to radius walls easily with no “cut-up” construction.

Saves Materials

Unlike job-built formwork, which must be tailored for each specific pour, the forming system comes in a variety of standard sizes which can be combined to form virtually any dimension. Panels and fillers are made of specially laminated plywood mounted on rugged steel frames. They can be used up to 200 times before being re-plyed.

Save time with easy set up & strip.

- No measuring, sawing, drilling, or nailing is required.

- Minimal training is needed, so workers are quickly up to maximum efficiency.

- Only two type of connecting hardware is required - Wedge Bolts & Long Bolts.

- No special tools required - just a carpenter's hammer.

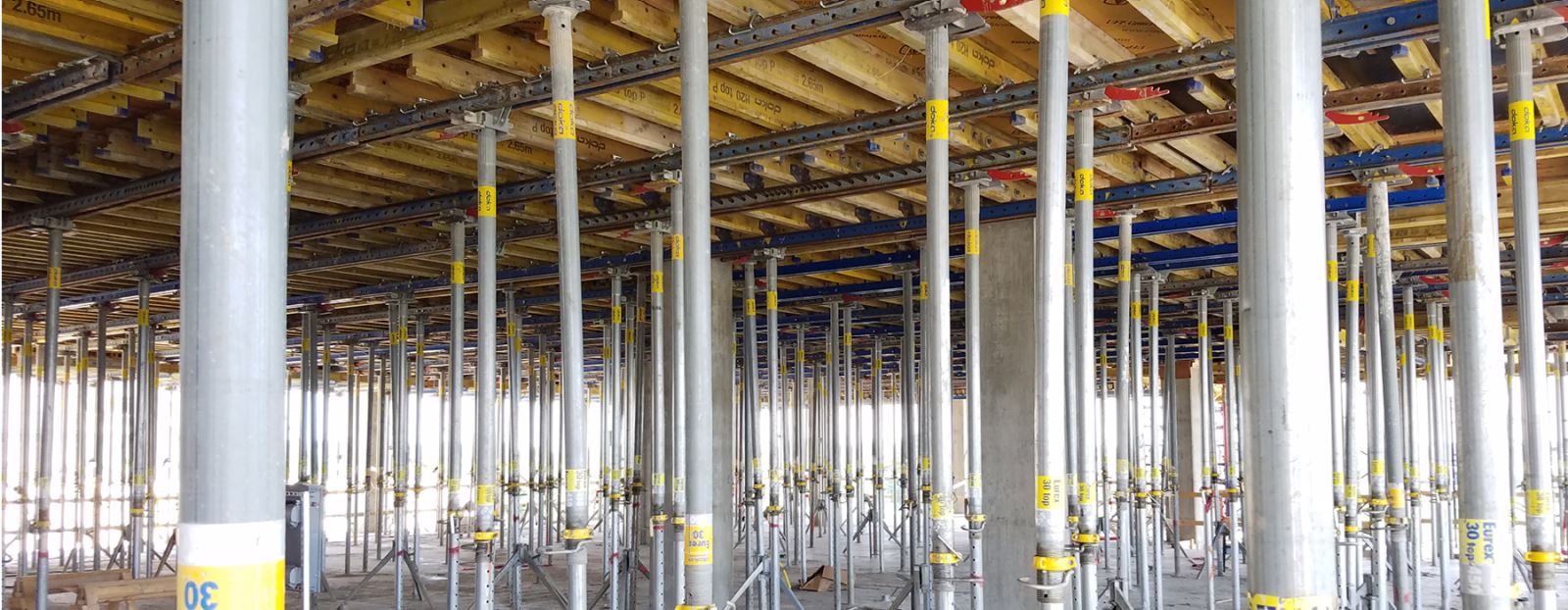

Shoring System

The 10k/leg shoring system is a proven method for shoring slabs at a wide range of heights and is especially effective for heights over 18 ft. Combining European technology with American methodology, the 10k system works well in conjunction with our Dokaflex and Dokamatic table systems.

Advantages

High leg load capacity combined with flexible a range of uses:

- Wide range of load capacity available up to 17,300 lb/leg.

- Frames are available in 2' or 4' widths and 3', 4', 5', or 6' heights.

- Cross braces are available in 3', 4', 5', 6', 7', 8', and 10' widths allowing the frames to be spaced from 3 ft. to 10 ft. apart.

Huge Flexibility to make work easier for your crew:

- H20/Steel W8 Beams, aluminum or steel junior beams are used for stringers.

- H20 timber beams or aluminum beams are used for joists.

- Darragh's engineering department will provide detailed layout drawings and calculations if required.

- Darragh maintains an inventory at our Little Rock and Benton warehouses which are available for immediate delivery.