Description

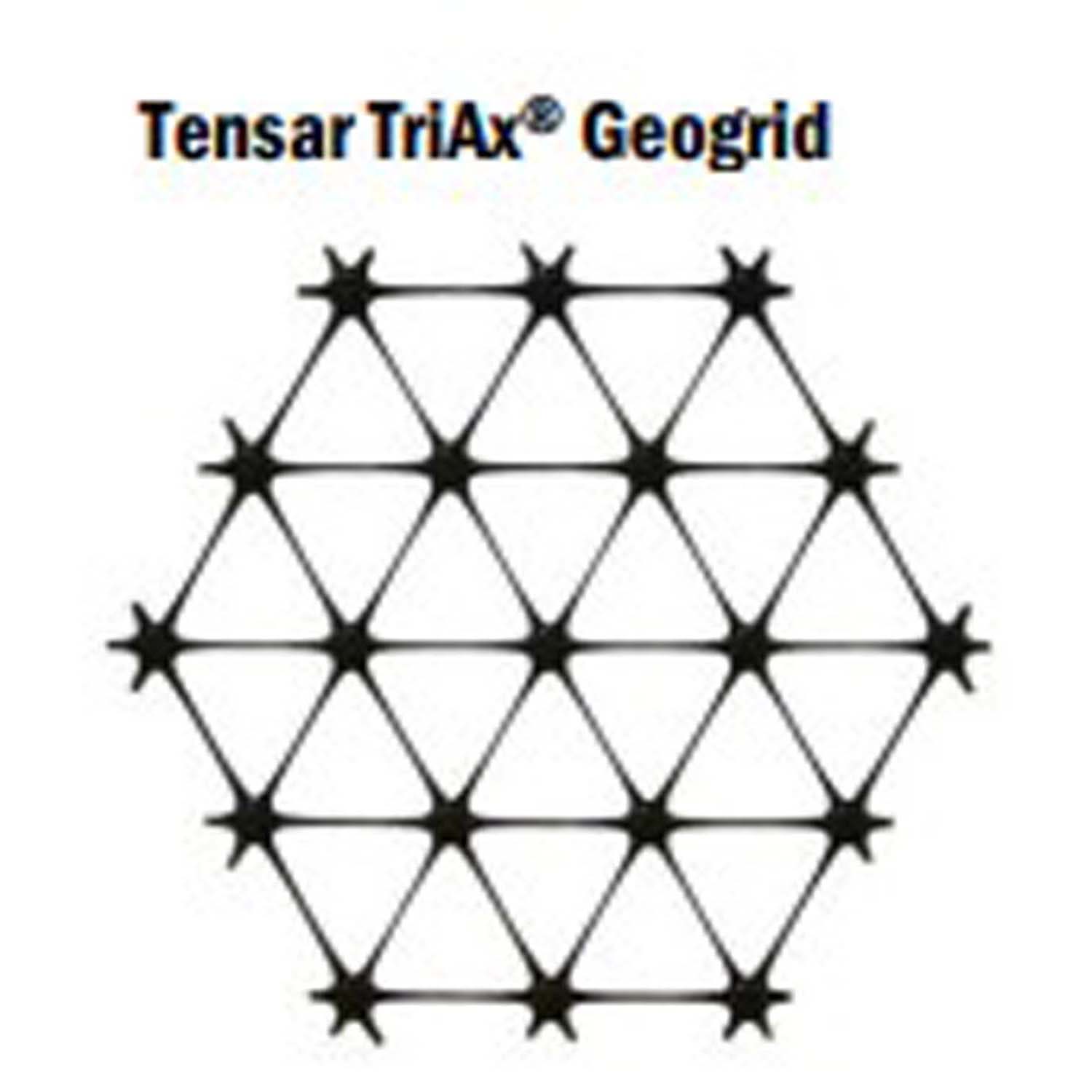

The geogrid is manufactured from a punched polypropylene sheet, which is then oriented in three substantially equilateral directions so that the resulting ribs shall have a high degree of molecular orientation, which continues at least in part through the mass of the integral node.

Key Features

- Index Properties:

- Rib pitch(2), mm (in): 33 (1.30), 33 (1.30)

- Rib shape: Rectangular

- Aperture shape: >1.0

- Rib Aspect Ratio(7)

- Structural Integrity:

- Junction efficiency(3) , %: 93

- Isotropic Stiffness Ratio(4): 0.6

- Durability:

- Resistance to chemical degradation(5): 100%

- Resistance to ultra-violet light and weathering(6): 70%

- Unless indicated otherwise, values shown are minimum average roll values determined in accordance with ASTM D4759. Brief descriptions of test procedures are given in the following notes.

- Nominal dimensions.

- Load transfer capability determined in accordance with ASTM D6637 and ASTM D7737 and expressed as a percentage of ultimate tensile strength.

- The ratio between the minimum and maximum observed values of radial stiffness at 0.5% strain, measured on rib and midway between rib directions.

- Resistance to loss of load capacity or structural integrity when subjected to chemically aggressive environments in accordance with EPA 9090 immersion testing.

- Resistance to loss of load capacity or structural integrity when subjected to 500 hours of ultraviolet light and aggressive weathering in accordance with ASTM D4355.

- Ratio of the mid-rib depth to the mid-rib width.